Production and R&D

The group’s industrial processes cover a very diverse range of filters. Misfat filtration has always adopted a strategy of diversification and technology watch in order to always be among the best in the filtration sector.

The competitive advantages induced by the industrial process are reflected in its reliability and its ability to meet the requirements of international standards as well as the specifics set by customers. The flexibility of the process is also an important quality that ensures optimal responsiveness to demand. This quality is reinforced by the control of upstream and downstream logistics flows as well as by a high integration rate.

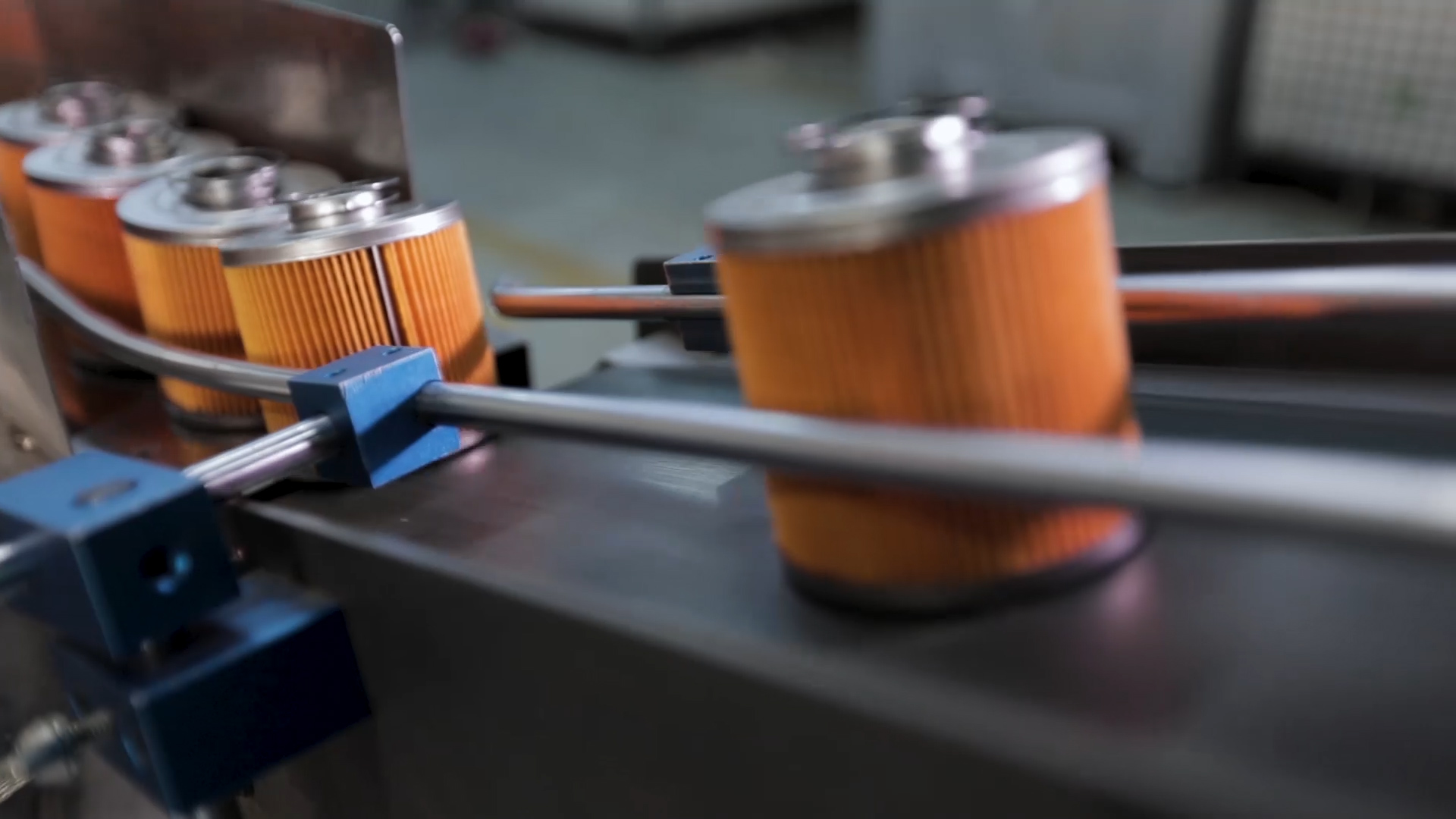

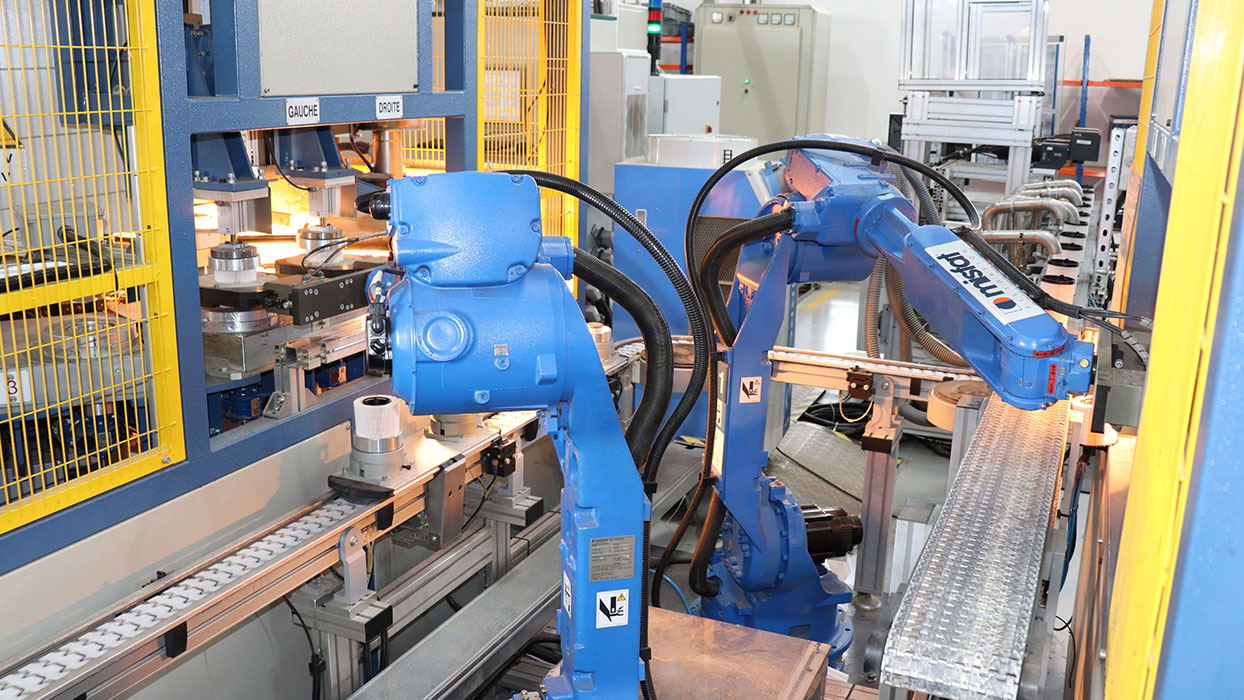

In search of performance and productivity, Misfat filtration continues to adapt its industrial capacity to its growth through the acquisition of automated processes. This allows it to achieve significant economies of scale.

In addition to its historic oil, fuel filter manufacturing plant and air and cabin filters with a capacity of 45 million filters / year, Misfat filtration has invested in a new fully automated factory dedicated to the manufacture of ecological filters. This unit was inaugurated in 2017.

To respect the “Original Equipment” quality level of its products, Misfat filtration has developed its engineering thanks to: